Our technologies

Experience and passion: We use proven technologies to meet your requirements!

Oxy-fuel cutting: 6 – 1400 mm plate thickness; up to 6000 mm width

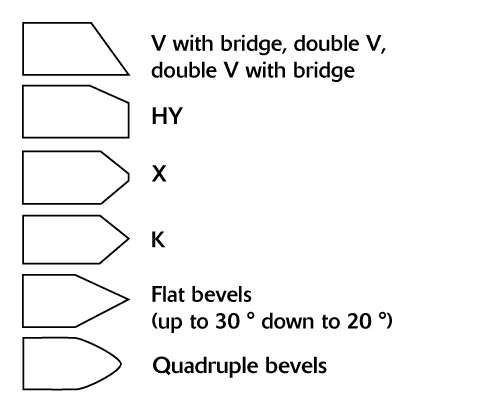

Robot oxy-fuel bevel cutting: Up to 200 mm

• 9 oxy-fuel flame cutting systems

• 1 oxy-fuel bevel cutting robot

Plasma cutting: 3 – 30 mm plate thickness

Robot plasma bevel cutting: 5 – 50 mm

We use two machines to perform plasma cutting:

1 plasma bevel cutting robot

1 double head plasma cutting system

Laser cutting: 1 – 20 mm plate thickness

Our 6 kW CO2 laser cutting machine can process plats with the size of 2500 mm x 12,000 mm.

Prefabrication – mechanical or thermal

We offer internal and external prefabrication:

cutting +++ drilling +++ threading+++chamfering thermal +++ bevel grinding +++ milling +++straightening +++blasting +++ painting

Blasting

With our continuous blasting machine, we process workpieces according to customer requirements (max. width of the workpiece: 3200 mm)

Straightening. Milling. Drilling.

Straightening by our straightening presses with a pressing force of 1200 t / 100 t and flame straightening: Flatness according to standard or agreement.

Our CNC-controlled milling machine enables precisely machined workpieces.

Our radial drilling machine cuts up to M 45 threads and drills diameters up to 80 mm.